Unveiling the Alchemy of Polymer Coatings: Redefining Gold Plating

Polymer Coatings: Embark on a Journey Towards Enhanced Gold Plating

In the realm of gold plating, polymer coatings emerge as a transformative force, elevating the durability and captivating radiance of gilded surfaces. Embark on a journey into their world, where we unveil the myriad benefits, explore the diverse types, and delve into the intricacies of application, curing, and quality control. Witness how polymer coatings are revolutionizing industries and transforming gold plating into an art form of unparalleled excellence.

Through this comprehensive exploration, you will gain an in-depth understanding of the transformative power of polymer coatings, enabling you to harness their full potential and create gold-plated masterpieces that stand the test of time.

Key Insights

- Polymer coatings significantly enhance the durability and allure of gold plating by providing superior protection against scratches, tarnish, and corrosion.

- A diverse range of polymer coatings is available, each tailored to specific applications and offering unique properties, such as acrylic, polyurethane, and epoxy coatings.

- Applying polymer coatings with precision requires careful surface preparation, proper application techniques, and adherence to curing methods to ensure optimal adhesion, coverage, and desired thickness.

- Implementing rigorous quality control measures, including coating thickness verification, adhesion testing, and wear and tear resistance evaluation, is essential to guarantee the highest standards of polymer coating performance.

- Polymer coatings are revolutionizing gold plating across industries, transforming product design and performance in jewelry, electronics, automotive, and beyond.

1. Introduction: Unveiling the Power of Polymer Coatings in Gold Plating

Introduction: Unveiling the Power of Polymer Coatings in Gold Plating

Embark on a captivating journey into the world of polymer coatings, where we unveil their transformative role in enhancing the durability and allure of gold-plated items. These coatings are the guardians of your precious gold, safeguarding it from the ravages of time and the elements.

Polymer coatings are not mere embellishments; they are the gatekeepers of gold’s radiance, preventing tarnish and maintaining its captivating luster. They provide an invisible shield against scratches, ensuring that your gold-plated treasures retain their pristine beauty. With polymer coatings, you can confidently adorn your creations or cherished heirlooms, knowing that their brilliance will endure for generations to come.

In this comprehensive guide, we will delve into the fascinating world of polymer coatings, exploring their myriad benefits, uncovering the diverse types available, and guiding you through the intricacies of application and curing. Embrace the transformative power of polymer coatings and elevate your gold plating endeavors to new heights of excellence.

2. Benefits of Polymer Coatings: A Comprehensive Exploration

Benefits of Polymer Coatings: A Comprehensive Exploration

Polymer coatings are not just an afterthought in the gold plating process; they are an investment in the longevity and beauty of your creations. By embracing these coatings, you unlock a treasure trove of advantages that will elevate your gold plating endeavors to new heights.

One of the most notable benefits of polymer coatings is their exceptional resistance to scratches. No longer will you have to worry about your gold-plated items succumbing to the wear and tear of everyday use. These coatings act as a protective barrier, shielding your precious metals from unsightly scratches and maintaining their pristine appearance.

Tarnish is another common enemy of gold, but polymer coatings stand as a formidable defense. They effectively prevent the formation of tarnish, ensuring that your gold-plated items retain their captivating luster for years to come. No more dull or discolored surfaces; instead, you will be rewarded with a brilliance that defies the passage of time.

In addition to their anti-scratch and anti-tarnish properties, polymer coatings also provide enhanced corrosion protection. This is of paramount importance, especially for gold-plated items that may be exposed to harsh environmental conditions. Polymer coatings act as a barrier against moisture and other corrosive agents, safeguarding your gold from deterioration and preserving its structural integrity.

3. Types of Polymer Coatings: Understanding the Options

Types of Polymer Coatings: Understanding the Options

The world of polymer coatings is a diverse and ever-evolving landscape, offering a wide range of options to cater to specific applications and desired properties. Each type of coating possesses unique characteristics, ensuring that you can find the perfect solution for your gold plating needs.

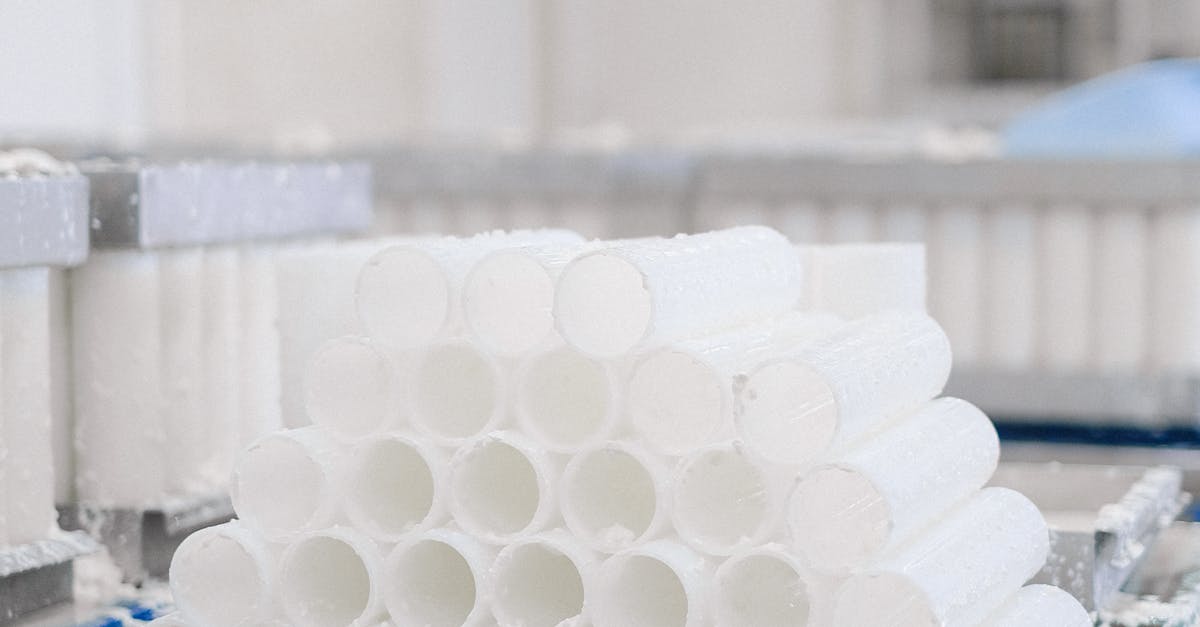

One of the most popular types of polymer coatings is acrylic. Acrylic coatings are known for their exceptional clarity and UV resistance, making them ideal for applications where transparency and protection from sunlight are paramount. They offer a glossy finish and are relatively easy to apply, making them a popular choice for both indoor and outdoor applications.

Polyurethane coatings are another widely used type of polymer coating. They are renowned for their toughness, flexibility, and resistance to abrasion. Polyurethane coatings provide excellent protection against scratches and wear, making them ideal for jewelry, watches, and other items that may be subjected to frequent handling. They also exhibit good adhesion to a variety of surfaces, ensuring a durable bond with the underlying gold.

Epoxy coatings are known for their exceptional chemical resistance and durability. They are often used in industrial applications where exposure to harsh chemicals or solvents is a concern. Epoxy coatings provide a hard, protective finish that can withstand extreme temperatures and provide excellent corrosion protection. While they may not offer the same clarity as acrylic coatings, they are an excellent choice for applications where durability is the top priority.

4. Application Techniques: Mastering the Art of Precision

Application Techniques: Mastering the Art of Precision

Applying polymer coatings with precision is an art form that requires a keen eye, steady hand, and a deep understanding of the materials involved. By following these techniques, you can ensure optimal adhesion, coverage, and desired thickness, resulting in a flawless finish that will enhance the beauty and longevity of your gold-plated items.

Before applying the polymer coating, it is crucial to prepare the gold surface thoroughly. This involves cleaning the surface to remove any dirt, oil, or debris that may interfere with adhesion. Once the surface is clean, apply a thin, even layer of the polymer coating using a brush, spray gun, or dipping method. The choice of application method will depend on the type of coating being used and the desired thickness.

After applying the first coat, allow it to dry completely before applying subsequent coats. This will ensure that each layer adheres properly and contributes to the overall thickness and durability of the coating. Use multiple thin coats rather than one thick coat to achieve the desired thickness and avoid runs or drips. Once the final coat has been applied, allow it to cure completely according to the manufacturer’s instructions. This curing process is crucial for developing the coating’s full strength and protective properties.

5. Curing Methods: Achieving Optimal Performance

Curing Methods: Achieving Optimal Performance

Curing is a critical step in the application of polymer coatings, as it is the process by which the coating solidifies and develops its full strength and protective properties. Different types of polymer coatings require different curing methods, and understanding these methods is essential to ensure optimal performance and long-lasting durability.

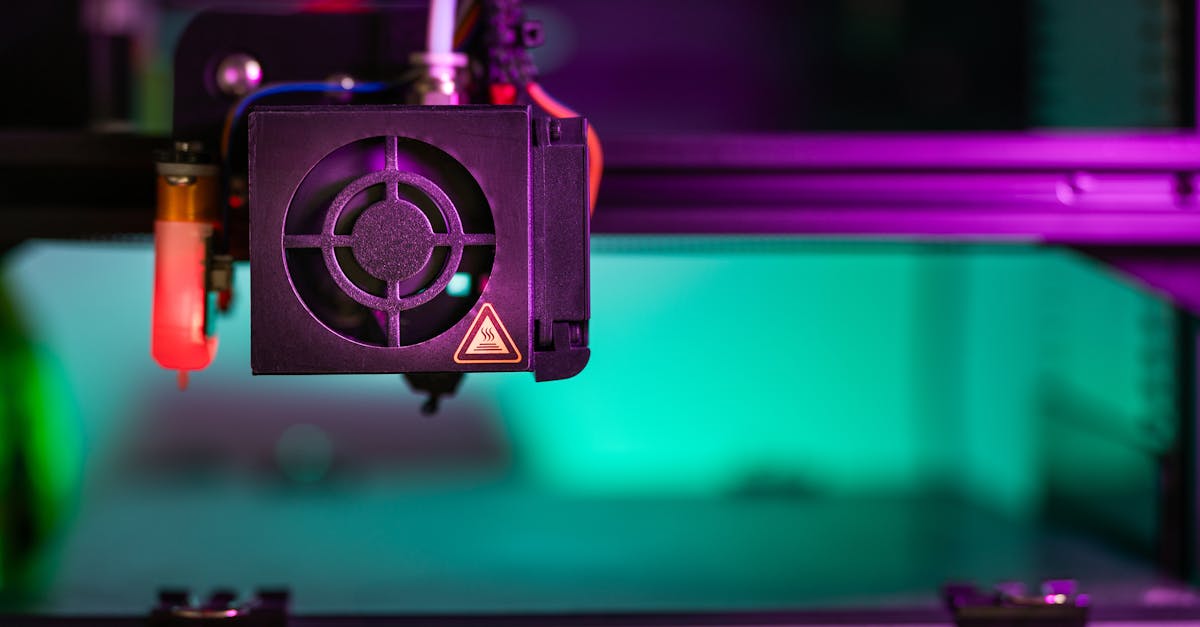

One common curing method is heat curing. This involves exposing the coated surface to elevated temperatures, either in an oven or with a heat gun. Heat curing accelerates the polymerization process, resulting in a hard, durable coating with excellent adhesion to the underlying gold surface. The specific temperature and duration of heat curing will vary depending on the type of polymer coating being used.

Another curing method is UV curing. This process utilizes ultraviolet light to initiate and accelerate the polymerization of the coating. UV curing is often used for thin coatings and can be a more energy-efficient method compared to heat curing. It is important to ensure that the UV light source is of sufficient intensity and wavelength to effectively cure the coating.

Regardless of the curing method used, it is important to follow the manufacturer’s instructions carefully to ensure proper curing and achieve the desired performance from the polymer coating.

6. Quality Control: Ensuring Excellence in Every Application

Quality Control: Ensuring Excellence in Every Application

Implementing rigorous quality control measures is paramount to ensuring the highest standards in polymer coating applications. By verifying coating thickness, adhesion, and resistance to wear and tear, you can guarantee the quality and durability of your gold-plated items.

Coating thickness is a critical factor that determines the protective and aesthetic properties of the coating. Using a thickness gauge, you can accurately measure the thickness of the coating and ensure that it meets the desired specifications. Adhesion is another important aspect of quality control. Poor adhesion can lead to peeling or flaking of the coating, compromising its protective properties. Adhesion testing methods, such as tape tests or pull-off tests, can be employed to assess the bond strength between the coating and the underlying gold surface.

Resistance to wear and tear is essential for ensuring the longevity of the coating. Wear and tear testing, such as abrasion tests or scratch tests, can simulate real-world conditions and evaluate the coating’s ability to withstand wear and tear. By implementing these quality control measures, you can ensure that your polymer coatings meet the highest standards of quality and performance.

7. Applications: Transforming Industries with Enhanced Gold Plating

Applications: Transforming Industries with Enhanced Gold Plating

Polymer coatings are revolutionizing the world of gold plating across a diverse range of industries, including jewelry, electronics, and automotive. These coatings not only enhance the beauty and durability of gold-plated items but also open up new possibilities for product design and performance.

In the jewelry industry, polymer coatings play a vital role in protecting delicate gold-plated pieces from scratches, tarnish, and wear and tear. They preserve the luster and brilliance of gold, ensuring that cherished jewelry pieces can be enjoyed for generations to come. Polymer coatings also allow jewelers to experiment with different colors and textures, creating unique and eye-catching designs.

In the electronics industry, polymer coatings are used to enhance the performance and reliability of electronic components. They provide protection against corrosion, moisture, and extreme temperatures, ensuring that electronic devices can withstand harsh operating conditions. Polymer coatings also play a crucial role in miniaturization, enabling the development of smaller and more compact electronic devices.

In the automotive industry, polymer coatings are used to enhance the aesthetics and durability of gold-plated components, such as emblems, trim, and wheels. They protect these components from the elements, preventing tarnishing and corrosion. Polymer coatings also provide a high-gloss finish, enhancing the visual appeal of vehicles and making them more resistant to scratches and wear.

What factors should be considered when choosing a polymer coating for gold plating?

When choosing a polymer coating for gold plating, several factors should be considered, including the desired properties, such as scratch resistance, tarnish prevention, and corrosion protection. Additionally, the compatibility of the coating with the specific gold-plating process and the intended application of the gold-plated item should be taken into account.

How can the durability of polymer coatings on gold plating be maximized?

To maximize the durability of polymer coatings on gold plating, proper application techniques, including surface preparation and proper curing methods, are crucial. Additionally, choosing a coating with the appropriate properties for the intended application and implementing rigorous quality control measures to ensure the coating meets the desired specifications are essential.

Are there any emerging trends or advancements in polymer coatings for gold plating?

Yes, there are ongoing advancements in polymer coatings for gold plating. Research and development efforts are focused on developing coatings with improved properties, such as enhanced scratch resistance, self-healing capabilities, and increased flexibility. Additionally, there is a growing emphasis on eco-friendly and sustainable polymer coatings that minimize environmental impact.

Table of Key Insights

| Key Insight | Description | |—|—| | Polymer Coatings Enhance Durability and Radiance | Polymer coatings provide superior protection against scratches, tarnish, and corrosion, enhancing the durability and allure of gold-plated items. | | Diverse Range of Polymer Coatings | A variety of polymer coatings are available, each tailored to specific applications and offering unique properties, such as acrylic, polyurethane, and epoxy coatings. | | Precision Application Techniques | Applying polymer coatings with precision requires careful surface preparation, proper application techniques, and adherence to curing methods to ensure optimal adhesion, coverage, and desired thickness. | | Rigorous Quality Control | Implementing rigorous quality control measures, including coating thickness verification, adhesion testing, and wear and tear resistance evaluation, is essential to guarantee the highest standards of polymer coating performance. | | Industry-Wide Applications | Polymer coatings are revolutionizing gold plating across industries, transforming product design and performance in jewelry, electronics, automotive, and beyond. |